Time-resolved microscopy and model-based analysis

of transparent conductive oxides thin-film ablation by spatial and temporal shaped ultrashort pulsed laser radiation

Prof. Dr. Heinz Huber

Department Applied Sciences and Mechatronics

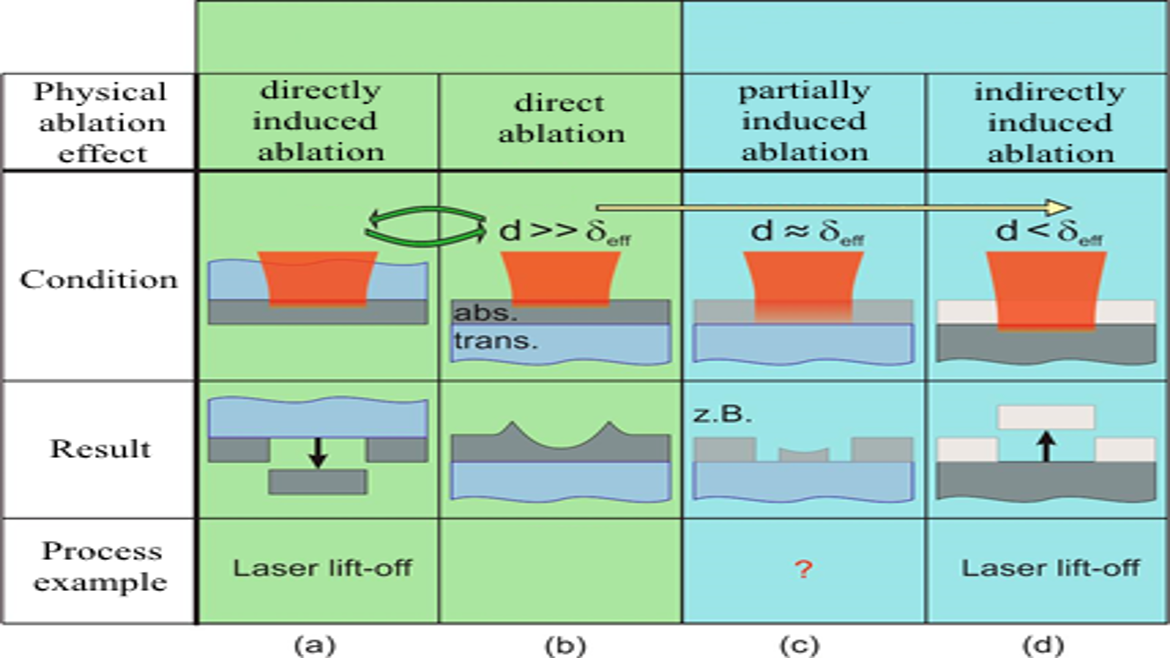

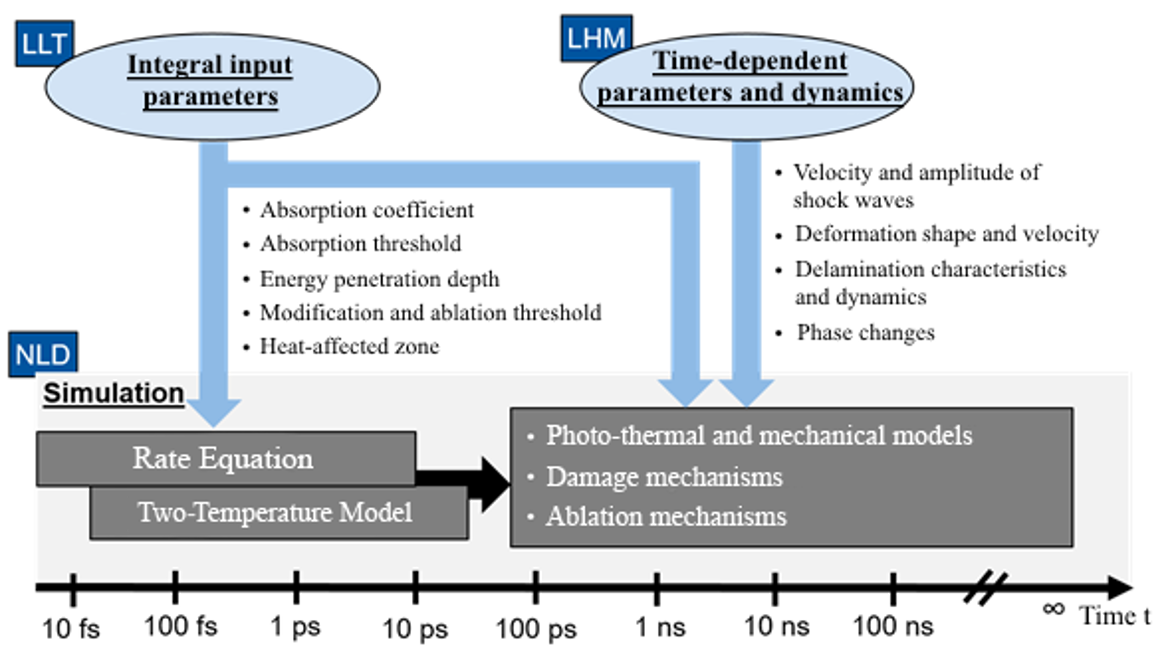

In this project, a basic understanding of the so-called partial and indirectly induced laser ablation of transparent, conductive layers using ultra-short pulsed laser radiation applied to ITO (Indium tin oxide) is to be developed. Partial and indirectly induced laser ablation are sub-types from confined laser ablation, in which an ultrafast laser pulse generates a stress confinement situation. The project goal is a description in the form of a metamodel, which is obtained from simulations and experimental data. By selective use of this laser-induced ablation, electrically conductive structures are separated or structured producing functional surfaces for components, such as front electrodes of a light-emitting diode. Since the components often consist of several thin films with layer thicknesses in the range of a few tens of nanometers up to 100 nanometers, defects such as ridge formation at the edge of the ablation site can lead to short circuits and consequently to the failure of the component. To manipulate or even prevent such defects, a thorough understanding of the ablation process and the physical interactions involved is necessary. In order to identify these mechanisms of action, the essential driving forces of the ablation process, and to guide the development of a mathematical-physical model, experimental process observables are investigated. These observables, on one hand, describe the dynamics of the process (transient measurements) and on the other hand the energetic study (steady-state measurement). The ablation criteria with respect to the quality of the ablated craters are determined by the steady-state parameters. Ultrafast time-resolved pump-probe microscopy experiments are to shed light on the physicals processes during the laser ablation. This provides crucial information for the development of the metamodel. The simulative and experimental results are used for the iterative development of a metamodel. A metamodel is a computational look-up table for the continuous approximation of the relation between parameters and criteria (process map). Compared with the analysis of data from single simulation runs or experiments, the metamodel allows a global analysis using rigorous, mathematical methods on interpolated, arbitrarily dense data. At the end of the project, the developed metamodel is expected to predict measurable and verifiable target variables such as ridge heights, substrate damage, insulation resistances, and crack lengths as a function of the process parameters.

Running duration:

01.10.2019 - 30.09.2022

Funded by:

German Research Foundation, (Deutsche Forschungsgemeinschaft, DFG, HU 1893/5-1)

Project Partner:

- RWTH Aachen University, Prof. Wolfgang Schulz, Lehr- und Forschungsgebiet Nichtlineare Dynamik der Laserfertigungsverfahren NLD,

- RWTH Aachen University, Dr.-Ing. Arnold Gillner, Lehrstuhl für Lasertechnik LLT