iSCUP

Repair and strengthening of reinforced concrete structures by using thin UHPFRC shotcrete layers: applications areas, design, durability, processing technology

Prof. Dr. Ing. Jörg Jungwirth

Prof. Dr. Ing. Andrea Kustermann

Prof. Dr. Ing. Christoph Dauberschmidt

Faculty of Civil Engineering

In the sector of infrastructure (bridges, tunnels, parking garages) as well as in the sector of building construction, the structure is typically 30 to 80 years old. Many of these structures are in a damaged condition due to chloride attack and loading. An evaluation of the damage to the steel bridges and prestressed concrete bridge in the road system of the Federal Republic of Germany shows that about 66% of the damage is due to chloride induced corrosion. There is currently a very great demand for efficient repair and strengthening methods to reconstruct the old building structure.

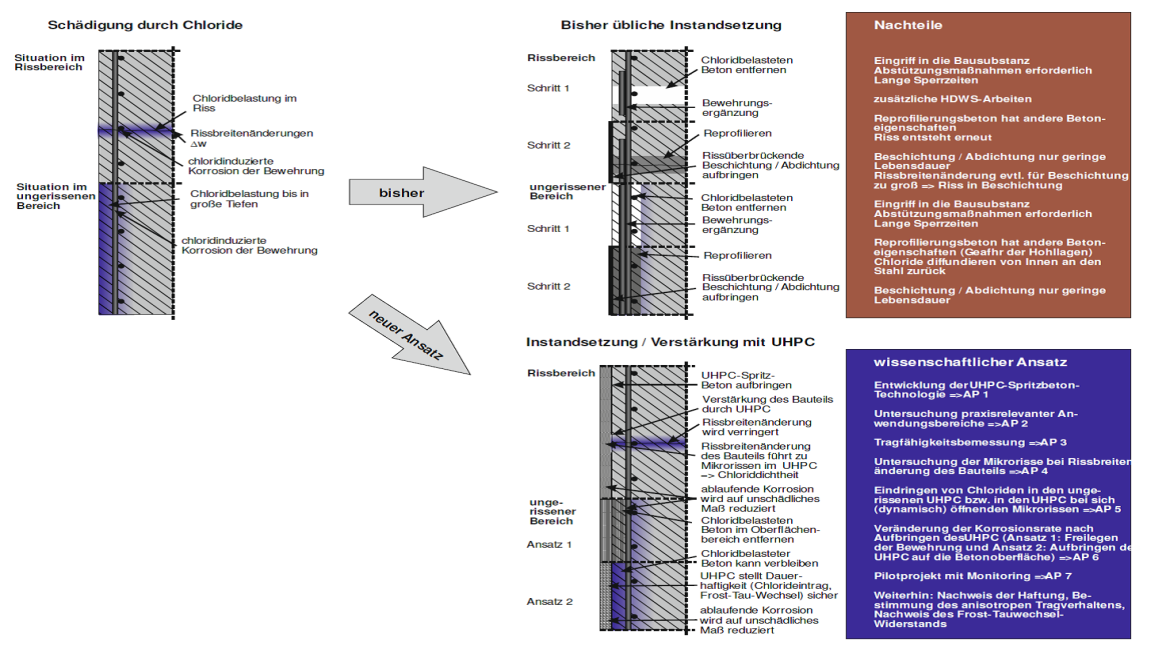

The established repair methods are usually associated with a major intervention into the structure, therefore it is expensive and time consuming. This leads to long blocking of intensive used transport infrastructure during repair. In addition, the regular caulking and sealing coat systems are usually not able to protect the infrastructure buildings from further damage over the rest of the lifetime. Optimized repair and strengthening systems are developed by using the innovative material ultra-high performance fibre reinforced concrete. The material is applied for the first time as UHPFRC shotcrete in thin layers. This technology simplifies the repair and optimizes the time consuming. A positive static effect of using UHPFRC shotcrete is that the material is applied where it is most efficiently, namely directly on the surfaces with the widest possible lever arm. In terms of the durability, the high density of UHPFRC can reduce the corrosion process on a low level due to the high electrolyte resistance, while the permanently protecting of the structure from the penetration of chloride attack.

The load-bearing behavior of the composite system is influenced by the interaction of the existing concrete with the UHPFRC shotcrete layer. The bond behavior and the time-dependent material behavior (shrinkage, creep) of the two cementuous materials must be considered. The compression stress of the composite UHPFRC-concrete element will increase directly due to the high compressive strength of the UHPFRC. Also an increase of the tensile strength of the composite element is achieved by effect of the fibre behavior. Using UHPFRC as a shotcrete has the positive effect, that it primarily aligns the fibres in parallel with the surface and it increase the tensile strength. For the absorption of high tensile stresses and the achieving of high deformation capacities, it is more efficient to integrate reinforcement elements (concrete steel, prestressing steel, textiles, etc.) into the UHPFRC layer. With the constricting effect of the fibre-reinforced UHPC it is possible to increase the load-bearing of columns (three-axial stresses state).

By using short and thin steel fibres, a crack-control effect can be achieved in a comparable way to a crack-control minimal reinforcement. This will be achieved by the crack-crossing fibers, which (as an average) have a higher tensile strength than the surrounding matrix. The result is that one crack does not open wider, but secondary cracks arieses next to the major crack (comparable to crack-control of reinforced concrete). The crack spacing is only a few millimeters and the crack width is very small (Width 0.02 mm compared to 0.2 mm for reinforced concrete). The aim is that the UHPFRC layer is able to protect the reinforced concrete structure permanently from chlorides, even in the case of (dynamic) movements of the construction and the resulting changes of the widths of the microcracks. Due to the high electrolyte resistance of the UHPFRC, a significant reduction of the corrosion processes is expected.

The project aims to develop a repair method in which the with chlorides contaminated concrete can be remain in the structure and at the same time the UHPFRC layer strengthens the load-bearing capacity of the structure, as well as the durability over the rest of lifetime use.

The special feature of this research project is the close interaction of the design/load-bearing behavior issues with the material behavior and the durability problems. The excellent properties of load-bearing capacity and the durability of the UHPC will be optimally used, as well as the material is used economically efficiently. Two scientific assistants are apllied for a cooperative doctorate, therefore three universities have agreed to cooperate.

Running duration:

01.04.2019 - 31.03.2023

Funded by:

Federal Ministry for Education and Research, Junior-engineers 2016

Project Executing organisation:

VDI Technology Center

Project Partners:

- University of Siegen

- Bundeswehr University Munich

- HafenCity University Hamburg (HCU)

- Implenia Repair GmbH

- Lafarge Holcim

- Ductal