Research Project

Innovative Design and Manufacturing for Fiber Reinforced Plastic Components

Prof. Dr.-Ing. Klemens Rother

Institute for Materials and Building Research, IMB

Faculty of Mechanical Engineering, Automotive Engineering, Aircraft Engineering

Laboratory for Mathematics and Technical Mechanics

Developers and manufacturers of continuous fiber-reinforced plastic components have to face very great challenges in competition with other lightweight construction materials in order, above all, to minimize material usage and production costs. This begins with the design of the components that is as fiber-compatible as possible, with the difficult task of designing the best possible layer structure to achieve maximum strength and stiffness. In addition, the manufacturing process is characterized by high tolerance requirements for low component distortion and high costs due to complex processes in cutting and depositing, combined with a lot of waste of semi-finished products during component manufacture.

Within the framework of this project, innovative methods are being investigated which can significantly improve several aspects of the use of traditional fiber composite structures with continuous fibers by means of new design principles, design methods and innovative production technology. Consistent application of these design principles, design methods and manufacturing processes leads to better fiber composite components with higher strength and stiffness as well as to lower weight and material usage via more efficient material utilization, to significantly less distortion of the components during production and also to less waste via a more efficient, because simplified, filing technique. The methods are suitable for various manufacturing processes, such as RTM or prepreg based manufacturing. The effort for analysis and optimization is drastically reduced compared to traditional analysis methods.

The methods were developed by a team headed by Prof. em. Stephen W. Tsai from Stanford University and a group of international researchers, industry specialists and companies.

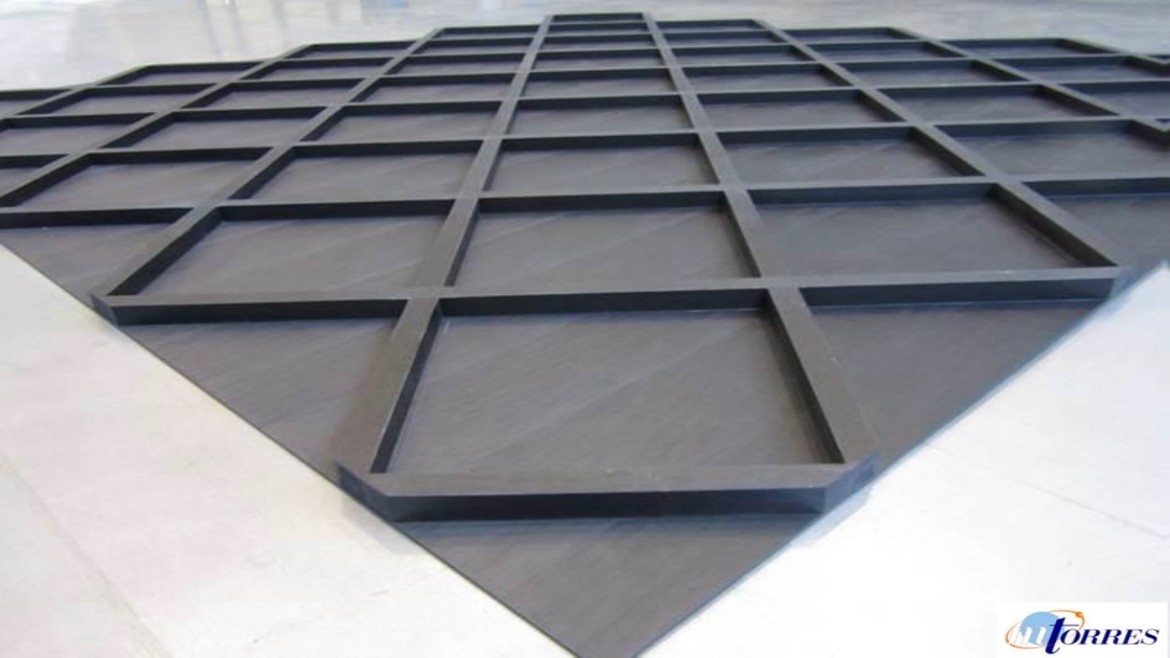

Main features of the new methods: Use of only three material parameters for the dimensioning of stiffness and strength, which makes it much easier to provide the necessary data for the design. For the layered structure, two layers with a double helix each - called double-double - are proposed to replace the traditional structure with 0, ±45 and 90°. This allows considerably thinner minimum wall thicknesses. Double-double laminates homogenize with only a few layers and already have symmetrical, distortion-minimizing structural properties even without a symmetrical layer structure. For example, a longitudinally stiff laminate with 20 single layers [05/±452/90]S can be replaced by a simpler structure with [±0/±50]5T. This makes the stacking process simpler and more error-free. Individual layers can be deposited flexibly according to structural-mechanical requirements, patch by patch and without the need for a symmetrical structure! Laminates can be realized as "orthotropic aluminum" with considerable thickness changes over the component surface - exceeding the previous limits. Such layer structures tend to have less microcracking, splitting or delamination. By using thin single layers and non-crimp fabrics, a new generation of applications can be achieved with a single axis deposition technique, with unsurpassed strength and a reduction of required mass and manufacturing costs.

Running duration:

since 2016

Project Partner:

Prof. em. Stephen Tsai D.Eng. Stanford University, Palo Alto, USA

and numerous other intl. partners from research and industry