LCF-Weld

Creation of consolidated and for engineering applicable methods for fatigue assessment of unmachined and reworked welded joints in the LCF area

Prof. Dr.-Ing. Klemens Rother

Faculty of Mechanical Engineering, Automotive Engineering

Institute for Material and Building Research IMB

Aeronautical Engineering

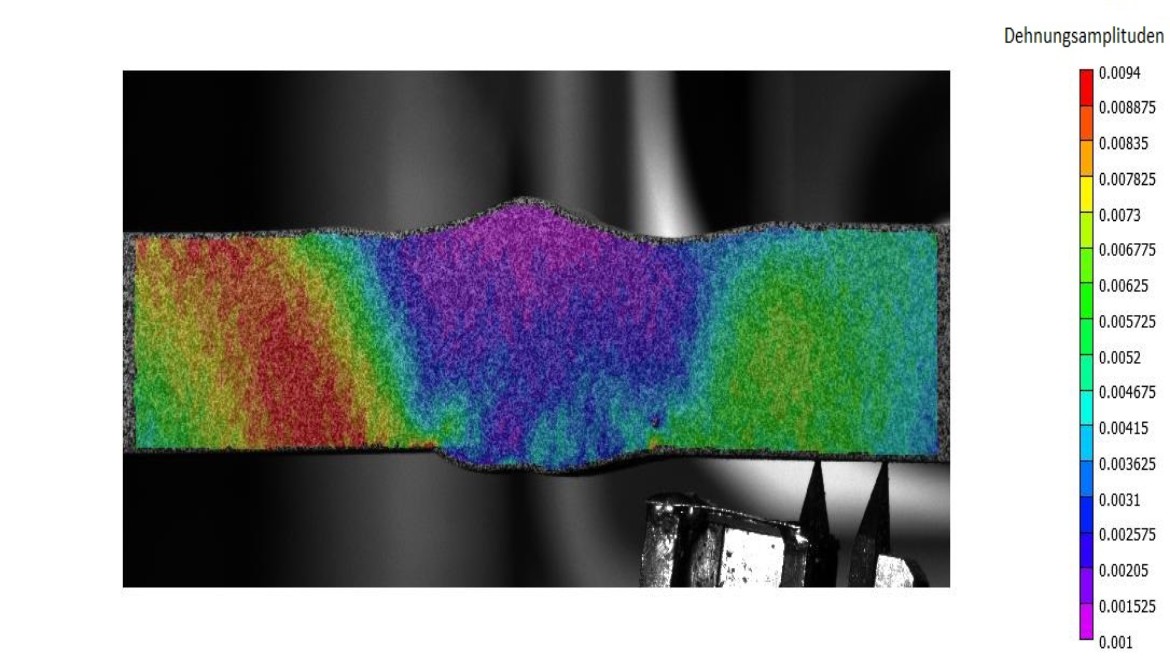

The subject of this research project is the investigation of the fatigue strength of welded joints at low cyclic fatigue. For this purpose, two very different materials on welded specimens with two wall thicknesses/seam thicknesses will be used to create the necessary experimental basis for the investigation and further development of computational concepts in the project.

The aim of the project is to develop improved lifetime concepts for welded joints made of the austenitic steel material X6CrNiTi18-10 (1.4541) and the high-strength structural steel S960M or comparable for purely low-cyclic stresses under constant amplitudes and plastic deformation and to validate them on the basis of experimental results. Local, material-based concepts as well as simplified correction functions for established stress-based concepts (nominal stress, structural stress, effective notch stress concepts) are used.

With an improved prediction capability in the purely low-cyclic range, it is hoped to create a basis for better predicting the service life of structures with load spectra that lie in the low-cyclic as well as the high-cyclic range. This goal helps to improve component reliability, thereby minimizing product risks in a wide range of industries and making the design more resource-efficient. Since product development in vehicle, machine and plant construction is increasingly being carried out by companies in the supply chain (engineering offices, development companies), the results are particularly relevant for SMEs.

Running duration:

01.04.2019 - 31.03.2021, extended until 31.03.2022

Funded by:

Federal Ministry of Economics and Energy

Project executing organisation:

Arbeitsgemeinschaft industrieller Forschungsvereinigungen, AiF

Forschungsvereinigung Schweißen und verwandte Verfahren e. V. des DVS

Project Partner:

Technical University of Darmstadt

Institute for Steel Construction and Mechanics of Materials

Department of Mechanics of Materials, Prof. Dr.-Ing. Michael Vormwald