StressPatches

Adhesive improvement of fatigue damages for steel construction structures

Prof. Dr.-Ing. Christian Schuler

Civil Engineering, Department 02

Fatigue stress is often a major challenge in the design of steel components. The service life of cyclically stressed steel structures, such as bridges, cranes, conveyor systems, masts or wind turbines, is determined by the fatigue strength of the design details used, which is classified by the so-called notch cases. The design is usually based on the application of the nominal stress concept, based on the fatigue strength catalogued Δσc for the specific notch class of the design detail.

However, for some years now there has been an increase in damage to steel structures stressed by fatigue. In national bridge construction, this can be seen, among other things, in an increasing deterioration of the condition grades of the bridge structures. Above all, conditions deviating from the original design, such as an extension of the operating time, changing external conditions (increased traffic volume, increased freight traffic performance) as well as production or execution-related errors in the construction or strengthening of the structures can lead to overstressing of the above-mentioned load-bearing structures and thus to damage.

In recent years BASt, among others, has carried out a number of investigations into fatigue damage and possibilities for the permanent strengthening of bridge components. The large number of investigations shows the necessity of new rehabilitation concepts and methods in the context of building maintenance.

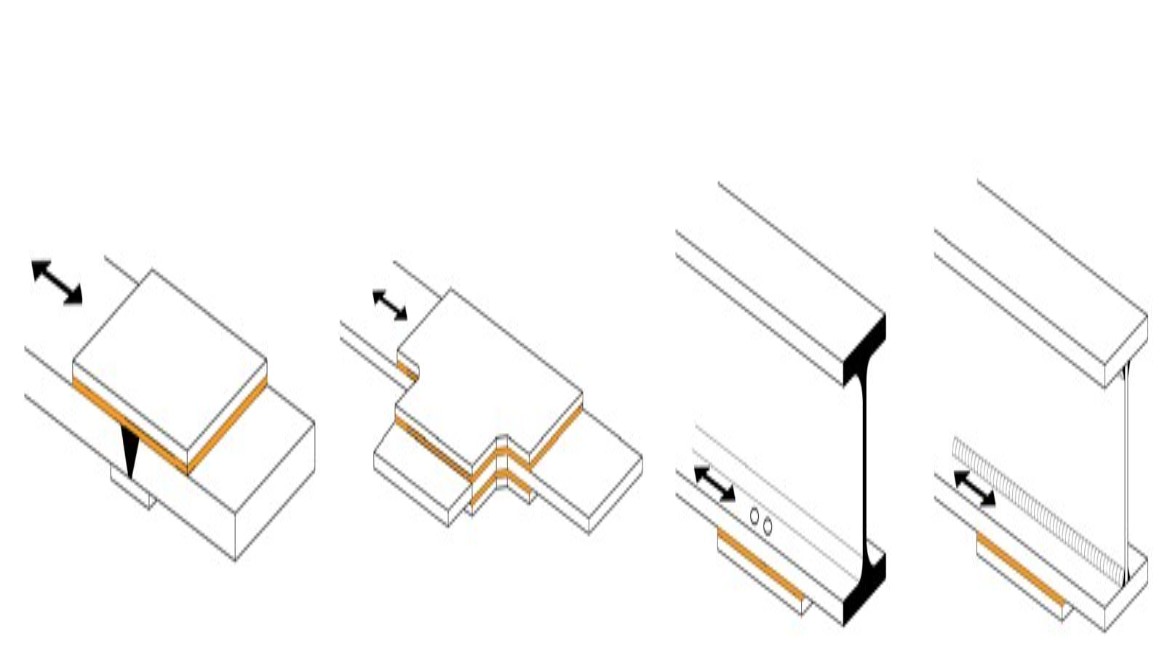

This is where this research project comes in: Adhesive concepts for the permanent strengthening and evaluation of high fatigue stressed notch cases of steel structures are developed and examined for their feasibility in order to reduce the stress level at the critical points and thus extend the service life of the structures.

Due to the homogeneous load introduction and transfer, strengthening by means of adhesive processes represents an alternative solution to conventional strengthening or repair methods such as welding and screwing without influencing the existing structure. This is because the use of welding solutions causes notches to be made in the microstructure again due to the thermal effects, which in turn are the starting point for crack formation. In the case of bolted strengthening variants, the cross-section is additionally reduced in addition to the notch introduced.

Running Duration:

01.02.2018 - 31.07.2020, extended until 30.04.2021

Funded by:

Federal Ministry for Economic Affairs and Climate Action

Project executing organisation:

Research Association for Steel Application (FOSTA)

Universitäre Partners:

- RWTH Aachen – Institut für Stahlbau

- Technische Universität Braunschweig – Institut für Füge und Schweißtechnik

Industrial Partners:

- 3M Deutschland GmbH, Neuss

- ArcelorMittal Europe - Long Products, Luxemburg

- Clean-Lasersysteme GmbH, Herzogenrath

- GIBmbH, Arnstorf

- Henkel AG & Co. KGaA, Garching b. München

- IB Grassl GmbH, München

- IBUKO Ingenieurgemeinschaft, Weingarten

- IFF GmbH, Ismaning

- Ing-Büro Wolf, Weingarten

- Kömmerling Chemische Fabrik GmbH, Pirmasens

- Konecranes (Terex MHPS GmbH), Düsseldorf

- Metallbau Ehard, Heideck

- Pfitzner GmbH Stahl- und Metallbau, Kierspe

- Sika Deutschland GmbH, Bad Urach

- Stockmeier Urethanes GmbH & Co. KG, Lemgo

- TÜV SÜD IS GmbH, München

- Verrotec GmbH, Mainz

- Bundesamt für Straßenwesen, Bergisch Gladbach