Research Project - Biomass-fired Boilers with Condensing Heat Utilization by Means of a Sorption Heat Pump

Research Project

Biomass-fired Boilers with Condensing Heat Utilization by Means of a Sorption Heat Pump

Prof. Dr. Christian Schweigler

Energy and Building Services Engineering, Department 05

The project aims at the development of a system for utilization of the condensing heat of biomass-fired boilers. For maximum efficiency regardless of the operating temperature of the heating system, e.g. a district heating network, an absorption heat pump (AHP) is applied, which serves for upgrading of the low-grade heat recovered from the wet boiler flue gas.

The development is targeted at medium (75 kW) to large size (some hundred kW) biomass boilers. Due to the heat input to the evaporator of the heat pump, the flue gas of the biomass-fired boiler is cooled down to about 20 °C, resulting in an enhancement of the boiler efficiency of about 30%, depending on the water content of the biomass fuel. In total about 25% fuel savings compared to conventional biomass boilers with flue gas outlet temperature of 180 °C and 85 % boiler efficiency shall be achieved.

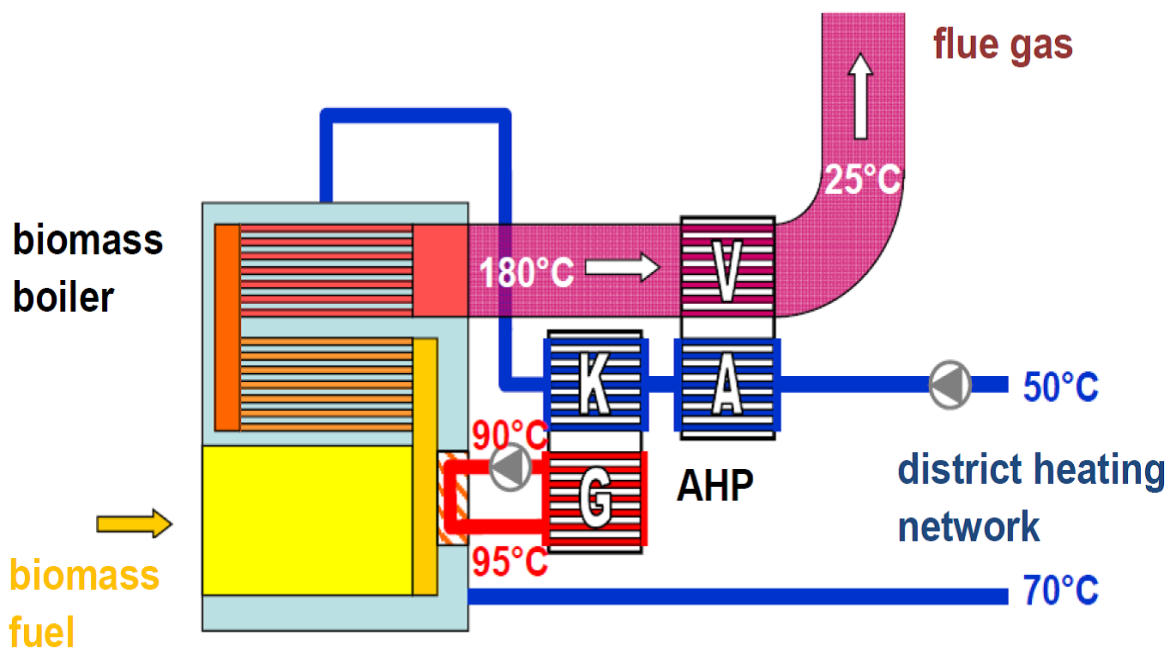

The concept is based on the integration of a heat pump into the heating system of the biomass boiler. The generated heat from the cooling and condensation of the flue gas is supplied to the evaporator of the heat pump working at a low temperature level around 20 °C. The required driving heat of a temperature level around 90 °C is provided by the biomass boiler. For that purpose the thermal design of the boiler is modified within the project. By means of the thermodynamic cycle of the thermally driven heat pump, heat is upgraded from a low temperature level to a higher temperature level. Both heat flows originating from the flue gas and the driving heat are transferred to the return flow of the district heating network by the condenser (K) and the absorber (A) at around 50 °C. A possible configuration of the system is presented in the following figure.

The project contains the following tasks:

- Thermal concept and layout of the heat pump cycle

- Modification of biomass boiler for integration of the sorption heat pump and provision of driving heat for the heat pump

- Design of the condensing flue gas heat exchanger

- Development of conceptual details of the sorption cycle e.g. thermosiphon design of the desorber, verification in laboratory testing

- Design of the sorption heat pump for low manufacturing costs and robust operation

- Design and construction of the sorption heat pump

- Erection and operation of a demonstration plant

Running Duration:

01.10.2017 – 30.09.2020, extended until 31.07.2022

Funded by:

Federal Ministry for Economic Affairs and Energy

Project executing organisation:

Project Management Jülich

Project Partner:

Scherdel Energietechnik GmbH