Enos

Dynamic Optimization of Refrigeration Supply Syste

Prof. Dr. Christian Schweigler

Energy and Building Services Engineering, Department 05

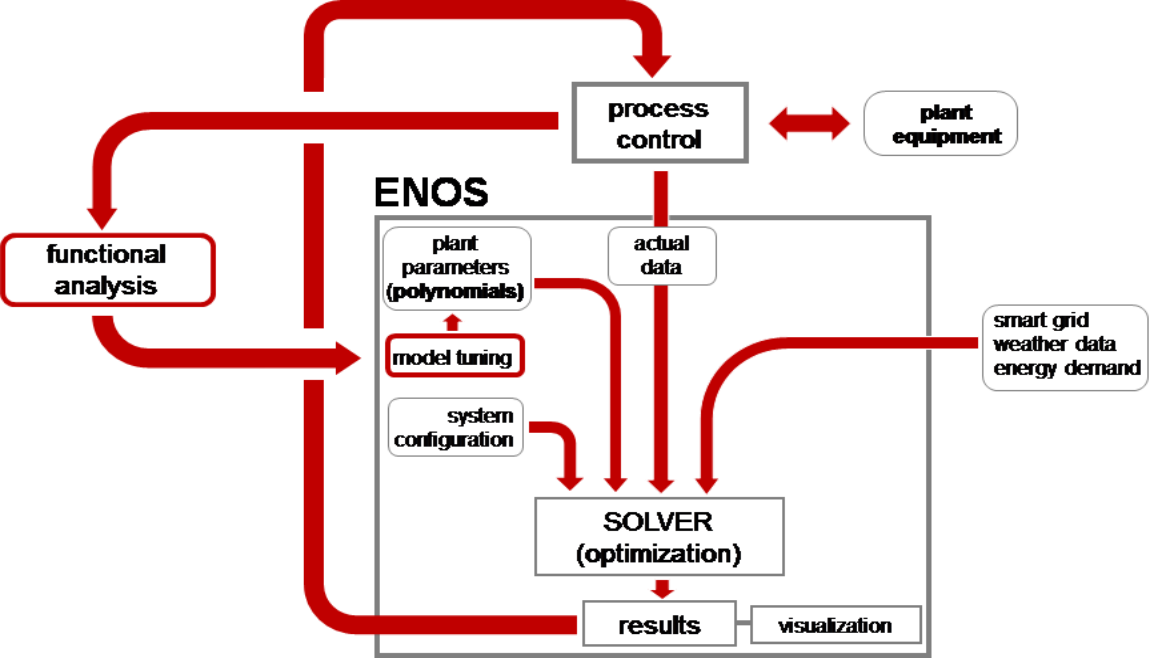

In refrigeration systems several devices are used interacting. This results in a high number of degrees of freedom with regard to the mode of operation of the individual units. A typical application is found e.g. when chillers are operated in conjunction with heat rejection units. Depending on the complexity and type of objective, different optimization procedures can be used to optimize the operation of these systems. The operating characteristics of all a system components must be modeled in sufficient quality. Overall, a considerable effort for the construction and application of a mathematical optimization of complex refrigeration systems is required. Within the framework of this study, a method will be shown to make the application of optimization methods also available for smaller refrigeration systems.

Simulation models with different model accuracy for the different components of refrigeration systems are developed. In this case, an exact physical description or different simplified empirical approaches can be used. The different component models are applied in conjunction with suitable optimization algorithms to determine which model accuracy is required in order to make a reliable statement about the optimal operating settings of the refrigeration system with the least possible computational effort.

When mapping the system characteristic or modeling the system, the applied modeling method should be as simple as possible. Since any increase in the level of detail of the model involves more effort in the creation and parameterization and requires a higher computing capacity in the application. Therefore, a main subject of the investigation is the clarification to which extent an increase of the model complexity makes sense. In search of suitable modeling methods for the compression refrigeration machine, two relevant fundamentally different model approaches are investigated. A detailed semi-empirical physical model contrasts with a highly simplified and generalized model.

Due to a high degree of flexibility and variety of refrigeration systems, a modular design of the models will be indispensable. Finally, it should be possible to create an individual system model with little effort. Furthermore, as soon as several chillers or heat rejection plants are to be used in combination, the optimization algorithm must be selected such that the on and off states of the components can be taken into account. Thus, starting from a quadratic or nonlinear optimization a mixed-integer nonlinear optimization problem (MINLP) is obtained, inducing a further increase of the complexity.

Running Duration:

01.01.2019 – 31.12.2021, extended until 31.12.2022

Funded by:

Federal Ministry for Economic Affairs and Climate Action

Project executing organisation:

Project Management Jülich

Project Partner:

Trane Roggenkamp GmbH